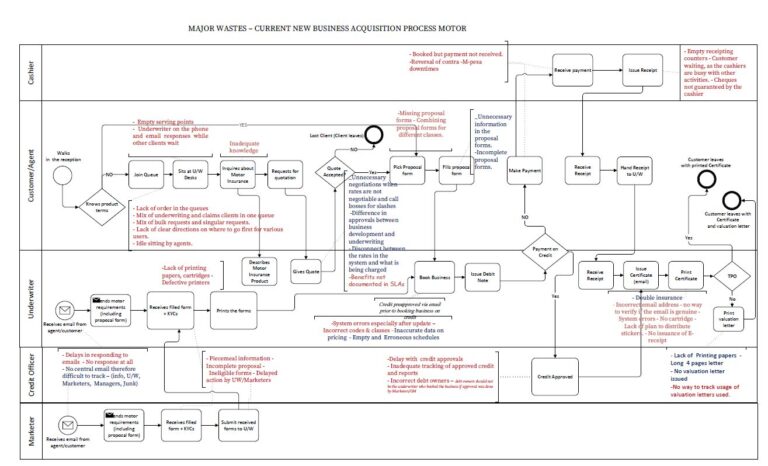

1. Map to Streamline BEFORE Automation

We uncover delays, errors or excess sign-off first, so automation amplifies efficiency instead of locking in bad processes. Solve the Root Cause!

We uncover delays, errors or excess sign-off first, so automation amplifies efficiency instead of locking in bad processes. Solve the Root Cause!

We guide IT and Operations teams to collaborate better, enhancing workflows, making daily work smoother and easier. Let Technology Make Your Work Easier!

We simplify change so it’s easy to understand, embrace, and champion at every level. You Lead; we support from the Back. Frustration Is a Sign of Change!

Whether we are in the room or on a call, we match your timeline and momentum to keep progress steady.

"I enjoyed most the enlightening teams on efficient ways of working and minimizing losses. Employees are more productive translating to customer satisfaction through reduction of lead times. The trainings have assisted us to better manage time thus greater output per person and more productivity."

"We gained numerous benefits from the engagement, but the most significant was the clarity it brought around our team dynamics—who we could truly count on, and who might be better suited elsewhere. For instance, we identified individuals with exceptional reliability and capacity, as well as those who were disengaged or misplaced. At a time when we were experiencing rapid growth and undergoing a senior management transition, it was crucial to upscale quickly—and your support was instrumental in making that possible. While the investment was substantial in the short term, the long-term value is already becoming clear.”

"My favorite part was it's intuitive, practical, hands-on, well customized with tailor made solutions to suit common place work place challenges Having acquired insightful knowledge on the categories of customers, with special focus on their different characteristics and applicable treatments for optimum elimination of inherent inefficiencies, there's palpable change in attitude which has translated into faster turnaround in projects and diminished repeat projects"

“Most favorite part was breaking processes down to their simplest form, and then being able to discuss these with staff in simple language that everyone understands. Once the scope was agreed, you just got on with it.”

"The training came at just the right time, as Sosiani takes off as a core site for Carbacid's future. Staff who once sat on the fence are now solution thinkers. Though virtual sessions worked, I recommend a mix with on-site attendance to eliminate tech hiccups"

"I enjoyed most your hands on approach and in depth engagement. Yes, I have learnt & benefited individually about business process improvement, the company has benefited with improved pricing, updated underwriting documents and customer service. There has been improved turnaround times in underwriting, update and automation of proposal forms and policy documents which have improved customer service."

"I really like the product delivery mode; you take time to understand the challenges, strengths and weaknesses of the clients. Overall, there is improved staff performance; contributed by reviewed/clear job description, harmonized benefits for the operations team. We reduced secondment costs by atleast USD 4,800 through improved team roles"

“Prompt objective feedback with SMART action points really helped. We were able to break down large challenges into small, doable, time-based activities that led us to practical solutions.”

You’ve got the certification—now it’s time to make it stick. Many professionals attend training but never complete their certification projects. We guide Lean and Six Sigma practitioners through real-world work—bringing clarity, structure, and momentum when it’s needed most.

Because unfinished projects mean missed opportunities, we help you move past roadblocks and see your hard work pay off.

Why join?

Why join?

Understand the 9 Lean wastes (TIMES EDGE) that slow down service and tech work.

Understand the 9 Lean wastes (TIMES EDGE) that slow down service and tech work. Learn through real-world examples you can relate to immediately.

Learn through real-world examples you can relate to immediately. Build a shared language with your team to identify and reduce waste.

Build a shared language with your team to identify and reduce waste. Walk away with practical steps you can apply the same day.

Walk away with practical steps you can apply the same day. Perfect for:

Perfect for: Quick Course—Lasting Impact

Quick Course—Lasting Impact Lean Banking Essentials

Lean Banking Essentials 3 Hours

3 Hours 💳 Banks and fintechs are pouring resources into new technologies—yet inefficiencies, delays, and customer frustrations still persist. This course is designed to give banking professionals and analysts the tools to see beyond the systems, identify hidden waste, and redesign workflows that truly improve both operations and customer experience.

Customer Effort & Flow — Surface where customers and teams feel friction.

Customer Effort & Flow — Surface where customers and teams feel friction. Lean Foundations for Banking — Why waste reduction matters (Muda, Mura, Muri).

Lean Foundations for Banking — Why waste reduction matters (Muda, Mura, Muri). Apply the 9-Wastes Lens — Use the TIMES EDGE perspective across onboarding/KYC, underwriting, payments, servicing, and digital/branch ops.

Apply the 9-Wastes Lens — Use the TIMES EDGE perspective across onboarding/KYC, underwriting, payments, servicing, and digital/branch ops. Impact & Metrics — Tie fixes to turnaround time, rework, risk, and Customer Experience.

Impact & Metrics — Tie fixes to turnaround time, rework, risk, and Customer Experience. Wrap-Up & Assignment — Apply the method to your own workflow and earn a certificate.

Wrap-Up & Assignment — Apply the method to your own workflow and earn a certificate. What You’ll Gain

What You’ll Gain Faster detection of bottlenecks and handoff delays.

Faster detection of bottlenecks and handoff delays. Tools to prioritize fixes with data and customer effort.

Tools to prioritize fixes with data and customer effort. Confidence to propose data-driven improvements that reduce cost and frustration.

Confidence to propose data-driven improvements that reduce cost and frustration. A shared language to align analysts, ops, and CX.

A shared language to align analysts, ops, and CX.

A recognized certificate of completion to strengthen your profile.

A recognized certificate of completion to strengthen your profile. Perfect for

Perfect for Analyze. Improve. Perform.

Analyze. Improve. Perform.

Green Belt prepares you to lead solutions—guiding teams, coaching change, and aligning improvements with business goals. You’ll strengthen your ability to analyze processes, prevent mistakes, and reduce variation. Some tools may be familiar from earlier levels, but now you’re expected to apply them in real work—coaching others, navigating complexity, and driving measurable results in your organization.

To earn your Green Belt certification, you must:

A recognized Lean Six Sigma Green Belt certification

While White Belt helps you see problems, Yellow Belt equips you with tools to solve them—clearly, confidently, and with measurable impact. You’ll learn to define issues precisely, analyze root causes, and apply structured methods like DMAIC to improve processes. Whether working independently or within a team, you’ll build skills to cut waste, raise quality, and drive lasting change.

To successfully complete this course, participants must:

This certification goes beyond awareness—it helps you change how you approach challenges at work. You’ll learn to identify everyday problems, reduce delays, and apply practical fixes that improve team performance, customer experience, and how it feels to get work done. With relatable examples, guided reflection, and real workplace application, the course builds lasting confidence to drive meaningful change.

To successfully complete this course, participants must: